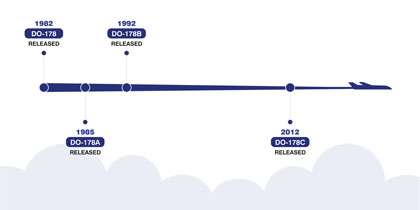

Evolution of standard: DO-178 to DO-178C

DO-178 was developed in the late 1970s and originally released in 1982. The original standard provided a prescriptive set of design assurance processes for software developed for airborne systems and focused on testing and documentation.

DO-178 was updated to DO-178A in the 1980s, with the update for the first time defining different levels of activities depending on the criticality of the system for which the software was written.

In 1992, DO-178B was released and was a total re-write of the existing DO-178 standard. Rather than the previously prescriptive processes described, DO-178B detailed a combination of activities and objectives that a design assurance process must meet. By defining activities and objectives only, airborne software developers had more flexibility in terms of development approaches. DO-178B did, however, specify key attributes for a design assurance process, derived from airworthiness regulations. For example, identifying unintended function and specific verification of software behavior whilst running on the final target hardware.

DO-178B also introduced the concept of the Design Assurance Level (DAL). DAL categorization determines the amount of rigor required by the design assurance process. DAL categorization itself is determined by the impact that a specific system's failure could have in terms of Aircraft Safety. The more critical the DAL, the more activities and objectives are required. DAL categorization continues to be used in DO-178C.